Biodiesel Processes

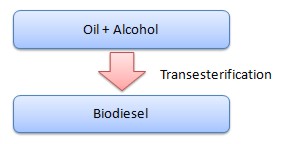

Transesterification

Applied when the oil has less than 1% of Free-Fatty Acids (in mass).

Usual operating conditions - mechanical stirring technology (batch reactor)

- Alcohol to oil ratio from 6:1 to 12:1

- Temperature from 30 to 60 oC

- Catalysts: hydroxides, methoxides and heterogeneous catalysts

- Catalyst concentraion: 0.5 to 2% w/w

Usual operating conditions - ultrasound technology (batch reactor)

- Alcohol to oil ratio from 6:1 to 9:1

- Temperature from 30 to 60 oC

- Ultrasound frequency: 25 to 40 kHz

- Catalysts: hydroxides, methoxides and heterogeneous catalysts

- Catalyst concentraion: 0.1 to 1% w/w

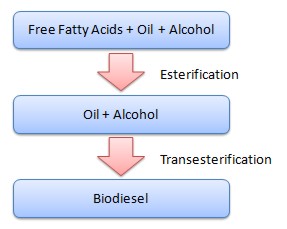

Esterification + Transesterification

Applied when the oil has more than 1% of Free-Fatty Acids (in mass)

Usual operating conditions

- Alcohol to oil ratio from 6:1 to 12:1

- Temperature from 30 to 60 oC

- Catalysts: strong acids

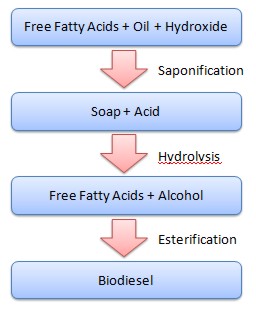

Saponification + Hydrolysis + Esterification

Applied when the oil has high percentage of Free-Fatty Acids (in mass)

Usual operating conditions

- Alcohol to oil ratio from 6:1 to 9:1

- Temperature from 30 to 90 oC

- Catalysts: strong acids